CGA Grading

Overview

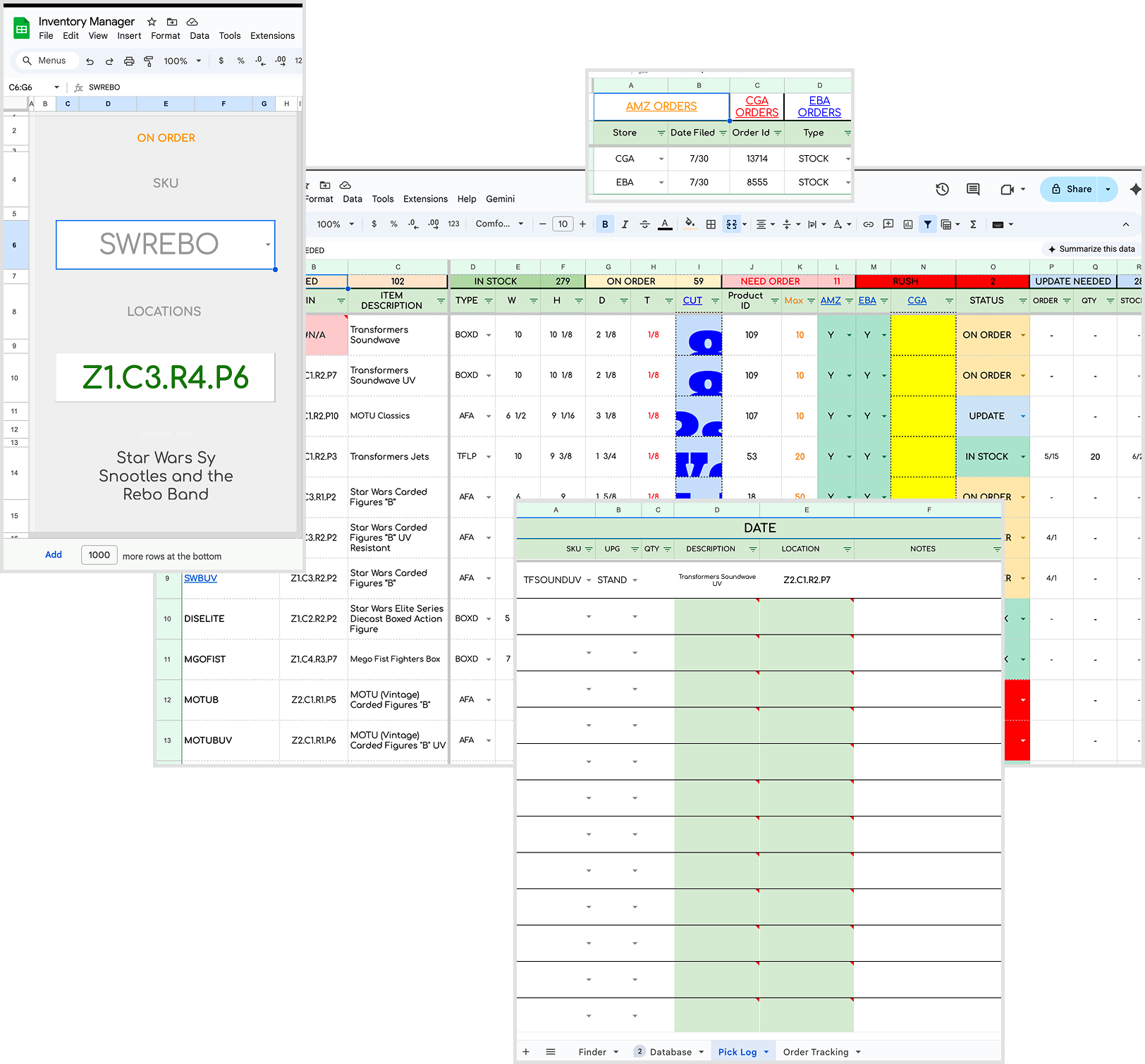

Operational Inventory System

When I joined, the company ran on paper. Printed grading forms. Filing cabinets. Hand written notes. Inventory location lived in people’s heads. Only long tenured team members and the CEO could reliably find items. As grading volume increased, inventory accuracy dropped, handoffs slowed everything down, and manual steps became a constant source of errors.

I stepped back and mapped the entire operation end to end. I replaced the paper based inventory with a structured spreadsheet system paired with a clear physical bin layout for the backroom. I then rebuilt the grading workflow itself, removing unnecessary handoffs, automating repetitive steps, and introducing system level synchronization where it added real value. Processing speed nearly tripled, manual work dropped by over sixty percent, and inventory became visible, reliable, and usable by anyone on the team.

Impact

- Scale: Paper based operations replaced with structured digital workflows

- Outcome: Nearly three times faster processing and sixty percent less manual work

- Google Sheets

- Process Design

- Inventory Logic

- Operational Mapping

- Bin System management

- Custom Scripts

- Automation Tooling

- Database Design

- Google Sheets

- Process Design

- Inventory Logic

- Operational Mapping

- Bin System management

- Custom Scripts

- Automation Tooling

- Database Design